Looking for a Particular Life Science Solutions Product?

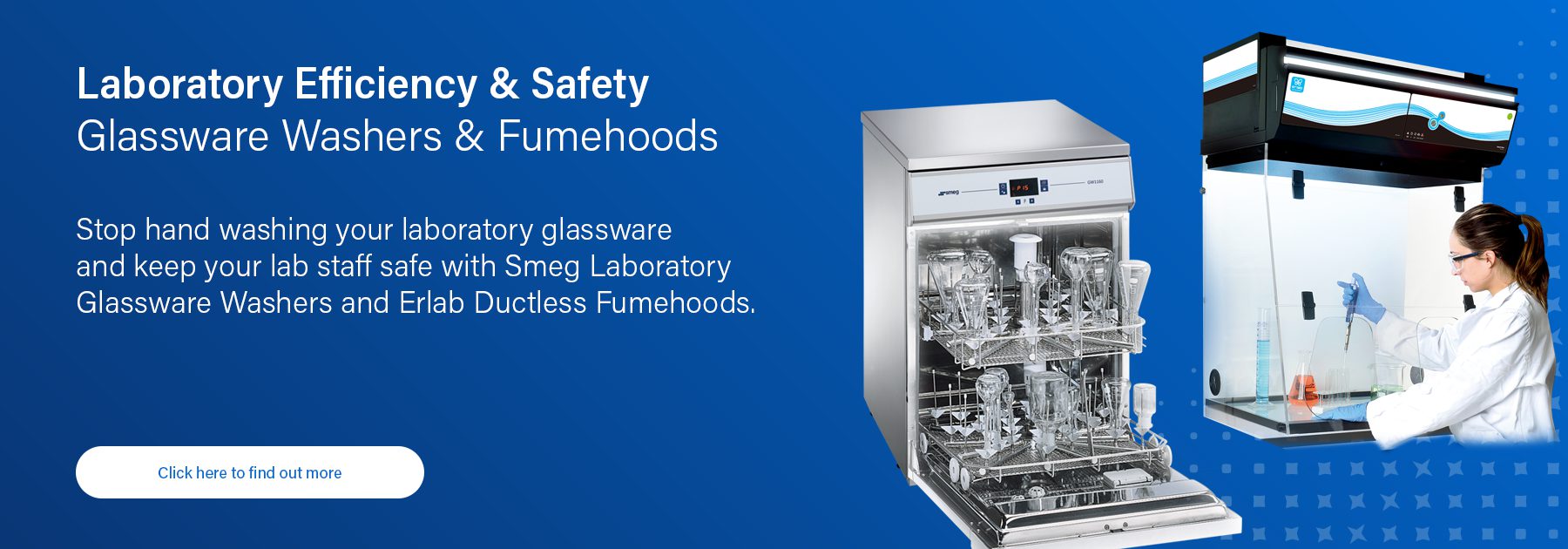

Fume Hoods and Filtration Solutions

Erlab are experts in air filtration, protecting the safety of lab personnel for ov...

view more Show more

Storage Filtration & Safety Solutions

Erlab's range of non-ducted vented storage cabinets are designed to protect labora...

view more Show more

Laboratory Air Safety Solutions

With their worldwide expertise Erlab offer a range of air filtration devices to ma...

view more Show more

Laboratory Glassware Washers

Belimed are one of the world's leading GMP washing & decontamination experts. ...

view more Show more

Ultrasonic Cleaning

Cavitation causes dirt residue and infectious agents in laboratory instruments pla...

view more Show more

Detergents, Cleaning & Rinsing Chemistry

Pairing the machine to the right chemistry is vital to ensure an optimum process w...

view more Show more

Laboratory & Pharmaceutical Steam Sterilisation

As a technology leader, Belimed Life Science offer over 40 years experience in lab...

view more Show more

Pharmaceutical (GMP) Thermal Disinfection

Cleaning processes play an essential role in pharmaceutical research and productio...

view more Show more

Process Monitoring

Monitoring the Cleaning, Washing and Sterilisation process in laboratories and pha...

view more Show more

Glassware Washer Accessories & Spare Parts

Rest assured we have your back with readily accessible equipment replacement consu...

view more Show more